https://nationalgrating.com/wp-content/uploads/2024/04/Minimal-Modern-Travel-Vlogger-Youtube-Channel-Art-1.png

1440

2560

Braden Taylor

https://nationalgrating.com/wp-content/uploads/2022/01/NG-Logo-JAN-2022-300x128.png

Braden Taylor2024-04-17 19:47:172024-04-22 16:27:44Eco Benefits and Sustainability of FRP Grating

https://nationalgrating.com/wp-content/uploads/2024/04/Minimal-Modern-Travel-Vlogger-Youtube-Channel-Art-1.png

1440

2560

Braden Taylor

https://nationalgrating.com/wp-content/uploads/2022/01/NG-Logo-JAN-2022-300x128.png

Braden Taylor2024-04-17 19:47:172024-04-22 16:27:44Eco Benefits and Sustainability of FRP GratingCall 1.844.599.0260 for more information.

FRP Applications and Markets

https://nationalgrating.com/wp-content/uploads/2024/04/Minimal-Modern-Travel-Vlogger-Youtube-Channel-Art-1.png

1440

2560

Braden Taylor

https://nationalgrating.com/wp-content/uploads/2022/01/NG-Logo-JAN-2022-300x128.png

Braden Taylor2024-04-17 19:47:172024-04-22 16:27:44Eco Benefits and Sustainability of FRP Grating

https://nationalgrating.com/wp-content/uploads/2024/04/Minimal-Modern-Travel-Vlogger-Youtube-Channel-Art-1.png

1440

2560

Braden Taylor

https://nationalgrating.com/wp-content/uploads/2022/01/NG-Logo-JAN-2022-300x128.png

Braden Taylor2024-04-17 19:47:172024-04-22 16:27:44Eco Benefits and Sustainability of FRP Grating

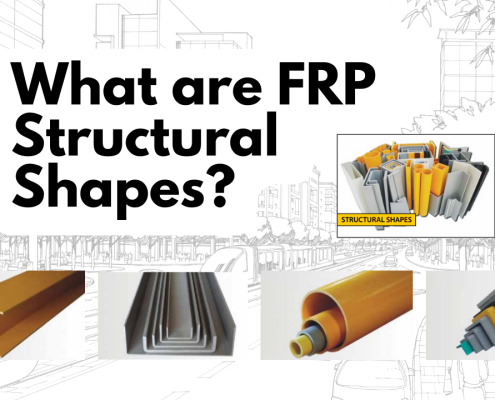

What are Fiberglass Reinforced Plastic (FRP) Structural Shapes, and what are they used for?

Fiberglass FRP Grating for Car Washes and Vehicle Maintenance Facilities

National Grating is the leading supplier of Fiberglass Grating in North America. We offer the lowest FRP Grating prices with exceptional service unmatched by any other FRP supplier.

With over 40 years’ experience, our skilled sales and customer service staff can help you determine the most cost-effective Fiberglass Grating solution for your next project. With locations throughout the USA and Canada, we can provide fast delivery from the nearest location to you.

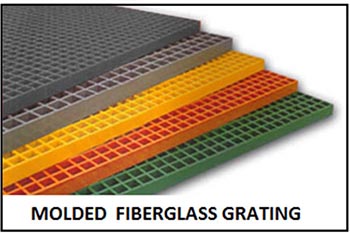

We specialize in fiberglass walkways, platforms, molded grating, non-slip FRP mesh and pultruded fiberglass bar grating. We also offer fiberglass reinforced plastic stair treads, fiberglass floor grating, trench drain grating, heavy-duty FRP grates and structural FRP fiberglass beams, angle, tube, plate and c-channel.

Fabrication Services

We can provide full FRP grating panels in sizes such as 3’ x 10’, 4’ x 8’ and 4’ x 12’ for molded grating and 3’, 4’ and 5’ wide pultruded grating up to 20 feet long. We can also cut the grating to size prior to shipping so it’s ready to install as soon as you receive it.

We’re Here to Help

Many of our customers are buying FRP products for the first time. They have many questions about the type of grating they need, how strong it should be, and how to order it.

Call us anytime. We are happy to discuss your application and offer suggestions on how to complete your project. Often molded grating with non-slip mesh is the best option and sometimes stronger, pultruded grating is better suited for longer spans. We will explain the pros and cons of each option and provide a competitive price quote within 24 hours. We look forward to hearing from you.

Contractors Across America Choose Us for Fiberglass Grating

With warehouse locations in Atlanta, Pittsburgh, Houston, Salt Lake City, and Canada, we can ship FRP Grating anywhere in America including:

New York State: New York City, Buffalo, Yonkers, Rochester, Syracuse

New Jersey: Newark, Jersey City, Paterson

Florida: Jacksonville, Miami, Tampa, Orlando, St. Petersburg, Hialeah, Port St. Lucie, Cape Coral, Tallahassee, Fort Lauderdale, Pembroke Pines, Hollywood

Texas: Houston, San Antonio, Dallas, Austin, Fort Worth, El Paso, Arlington, Corpus Christi, Plano, Irving, Lubbock, Laredo, Garland, Frisco, McKinney, Amarillo, Grand Prairie, Brownsville, Killeen, Mesquite, Pasadena, Denton

Ohio: Columbus, Cleveland, Cincinnati, Toledo, Akron

Pennsylvania: Philadelphia, Pittsburgh

California: Los Angeles, San Diego, San Jose, San Francisco, Fresno, Sacramento, Long Beach, Oakland, Bakersfield, Anaheim, Irvine, Stockton, Riverside, Santa Ana, Chula Vista, Santa Clarita, Fremont, San Bernardino, Modesto

Illinois: Chicago, Aurora, Naperville, Joliet, Rockford

Arizona: Phoenix, Tucson, Mesa, Chandler, Gilbert, Glendale, Scottsdale, Peoria, Tempe, Surprise

North Carolina: Charlotte, Raleigh, Greensboro, Durham, Winston-Salem, Fayetteville, Cary

Indiana: Indianapolis, Fort Wayne

Washington: Seattle, Spokane, Tacoma, Vancouver, Bellevue, Kent

Virginia: Virginia Beach, Chesapeake, Arlington, Norfolk, Richmond, Newport News, Alexandria

Tennessee: Nashville, Memphis, Knoxville, Chattanooga, Clarksville, Murfreesboro

Nevada: Las Vegas, Henderson, North Las Vegas, Reno, Enterprise, Spring Valley, Sunrise Manor, Paradise

Georgia: Atlanta, Columbus, Augusta, Savannah

Colorado: Colorado Springs, Aurora, Fort Collins, Lakewood, Thornton

Alabama: Huntsville, Montgomery, Birmingham, Mobile

The Most Responsive Fiberglass Grating and Structures Distributor!

Choosing National Grating means a quick quote on the right FRP product, prompt delivery and accurate paperwork. Contractors and volume purchases get special bulk pricing.

Fiberglass Grating, Railings, Structures and More!

Rely on National Grating for the molded and pultruded grating products that provide safe working platforms for WWTP, power stations and food processing facilities. Our durable, environmentally-friendly FRP products make for a lower total cost of ownership.

Ready to Deliver to Your Job Site!

We ship fiberglass grating to contractors in ALL USA States including California, Oregon, Alaska, Florida, New York, Illinois, Pennsylvania, Ohio, Georgia, Michigan, Virginia, Massachusetts, Arizona, Washington, North Carolina, Nevada, Texas, New Mexico, Indiana, Tennessee, Colorado, Maryland, Missouri, Wisconsin and Utah.

Resources

Popular Pages

FRP Specs & Topics

- What are people saying about National Grating?

- Eco Benefits and Sustainability of FRP Grating

- What are Fiberglass Reinforced Plastic (FRP) Structural Shapes, and what are they used for?

- Is FRP Grating better than Steel Grating?

- Fiberglass FRP Grating for Car Washes and Vehicle Maintenance Facilities

Fiberglass Grating & Structures

Fiberglass Grating & Structures